- Mount material on a firm backing—useful for photographs, painting, fabrics, and so on.

- Mount material on a flexible cloth backing to keep it pliable but tear-proof—useful for maps and charts that you want to roll.

- Laminate—especially useful for thick materials, such as plywood or masonite, which do not fit into an automatic laminating machine.

- Make transparencies through a heat-lifting process for overhead projector use.

The press has a thermostat control to set the temperature for each function.

Operating tips

- Before closing the press, cover the material with a heavy sheet of paper larger than the original so that no ridge marks will appear on the finished product. Blank newsprint provides good protection.

- For thick materials, know the maximum thickness of material that your machine will accept. Usually, presses can dry mount fairly thick boards.

- For thin materials, place a few sheets of cardboard in the press beneath the pad on which you place the material.

- For wide and long materials, use materials up to twice as wide as your material and of indefinite length. For long materials, start at the center and work toward either end. For wide and long materials, tack the material to dry-mount tissue, but do not tack it to the mounting board before dry mounting. This will help to prevent wrinkles on the final product.

Problems

| Problem | Cause | Solution |

| Air bubbles. | Moisture in either material or mounting board. | Wrap mounting board and material in brown wrapping-paper or art paper envelope. Place both mounting board and material in press for 30 seconds at 225 degrees. Remove, and prepare for mounting. |

| Thick material. | Keep in press longer. | |

| Not enough pressure. | Add some cardboard backing. Dry mount again. | |

| Wrinkles during dry-mount press lamination. | Wrinkles cannot be eliminated. | Use solutions below to prevent future wrinkles. |

| Film tacked to material before laminating. | Do not tack film to material before laminating. | |

| Insufficient heat. | Leave in press long enough. | |

| Surface of material not smoothed as it is placed in press. | Laminate one side at a time. Smooth material before mounting. Wrap in brown paper envelope before laminating. | |

| Material being laminated is soft. | Put cardboard under dry-mount press pad on which you lay material. | |

| Curling or warping of finished product. | Moist when put into press. | Before mounting, dry material in press for 30 seconds at 225 degrees. |

| Need pressure on finished product. | After mounting, place heavy book on material until cool. |

In-depth

I. Temperature settings

It takes about 11 minutes to warm up the press to 225 degrees.

Times and temperature in the table are approximate. Initially, use the minimum time and temperature necessary. You can always increase these or return your material to the press for a better job.

I. Temperature settings

It takes about 11 minutes to warm up the press to 225 degrees.

Times and temperature in the table are approximate. Initially, use the minimum time and temperature necessary. You can always increase these or return your material to the press for a better job.

| Function | Temperature setting | Backing material or tissue | Approximate time in press |

| Dry mount | 225°-250° | Dry-mount tissue and mounting board | 30-45 seconds |

| Laminating | 270°-350° | Laminating film | 1 minute + |

| Heat lifting | 270°-350° | Laminating film | 1 minute + |

II. Procedures for dry mounting

Equipment and materials: dry-mount press, tacking or clothes iron, scissors and/or paper cutter, your material, mounting board (such as poster board), dry-mount tissue, envelope of blank newsprint, brown paper, or art paper.

A. Select your material. Do not trim.

A. Select your material. Do not trim.B. Pre-heat the dry-mount press and the tacking iron.

C. Put the material face down. Place the dry-mount tissue on the back of the material.

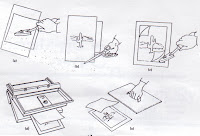

D. Use the tip of the iron to tack the tissue to the material. Tack at the centre and three-quarters of the way toward each corner. Think of a small x pattern. Do not tack at the corners. see Figure 5-1a.

E. Trim the material and the tissue to the same size. see Figure 5-1b.

F. Place the material on top of the mounting board. Center or position the material. Separate the picture from the loose tissue at the corner. Place the corner of the tissue against the mounting board while holding the picture in place. Touch the iron to the tissue so it will adhere to the mounting board. Repeat at one other corner. Omit this step for extra wide and long materials. see Figure 5-1c.

G. Wrap the material and the mounting board in blank newsprint, brown paper, or art paper envelope to protect it. You may also use release paper, which is a commercially available product. Place the waxed side next to your material.

H. Place in the dry-mount press. The material to be dry mounted should face up. Keep in the press at 224 degrees for 30 to 45 seconds. see Figure 5-1d.

I. Remove and inspect the materials for bubbles. Insert again if more heat is needed.

J. Place a heavy weight on the mounted material until cool. see Figure 5-1e.

K. The material is now ready to use.

L. Turn the dry-mount press off. Unplug the tacking iron.

III. Cleaning the machine

For stubborn deposits on the platen, use fine-grade emery cloth available at a hardware store, fine-grade (00 or 000) steel wool, or a razor blade. Wipe clean with soft damp cloth. Avoid marring the platen.

Glossary

Chartex Cloth backing (the side without cloth is adhesive). Use the dry-mount press at 225 degrees for 5 seconds.

Dry-mounting tissue Special waxy tissue paper coated on both sides with a heat-sensitive adhesive. When sandwiched between the print and the mounting material, it forms a bond between the two.

Fotoflat tissue Dry-mounting tissue that can be removed at a later date so that the original print can be separated from its backing. To dry mount, use the press at 180 degrees. To remove the backing, reheat the material at 200 degrees for one minute, then use a razor blade to separate the material carefully from the mounting board.

Heat lifting A process for making transparencies from paper originals for use with the overhead projector. It is especially helpful for converting magazine pictures into transparencies. Generally, use a magazine page that is clay-coated. Laminate only on the side of the desired picture, not on both sides. Soak laminated product in soapy water. Gently separate or rub away paper from film. The image will remain on the laminating film, and this film is your transparency.

Lamination Heat and pressure process of encasing and sealing material between two layers of plastic film.

Platen Metal surface on the inside cover of a dry-mount press, which conducts heat to your material. Tacking iron Essential accessory to dry mounting. This small iron is used to attach (tack) mounting tissue to your material and to the mounting board before they are put into the press. It is also useful in taking out air bubbles left on the finished product. (If a tacking iron is not available, use the tip of a clothes iron, not on steam setting.)

Tear sheet A term for the material you have selected to be dry mounted.

Chartex Cloth backing (the side without cloth is adhesive). Use the dry-mount press at 225 degrees for 5 seconds.

Dry-mounting tissue Special waxy tissue paper coated on both sides with a heat-sensitive adhesive. When sandwiched between the print and the mounting material, it forms a bond between the two.

Fotoflat tissue Dry-mounting tissue that can be removed at a later date so that the original print can be separated from its backing. To dry mount, use the press at 180 degrees. To remove the backing, reheat the material at 200 degrees for one minute, then use a razor blade to separate the material carefully from the mounting board.

Heat lifting A process for making transparencies from paper originals for use with the overhead projector. It is especially helpful for converting magazine pictures into transparencies. Generally, use a magazine page that is clay-coated. Laminate only on the side of the desired picture, not on both sides. Soak laminated product in soapy water. Gently separate or rub away paper from film. The image will remain on the laminating film, and this film is your transparency.

Lamination Heat and pressure process of encasing and sealing material between two layers of plastic film.

Platen Metal surface on the inside cover of a dry-mount press, which conducts heat to your material. Tacking iron Essential accessory to dry mounting. This small iron is used to attach (tack) mounting tissue to your material and to the mounting board before they are put into the press. It is also useful in taking out air bubbles left on the finished product. (If a tacking iron is not available, use the tip of a clothes iron, not on steam setting.)

Tear sheet A term for the material you have selected to be dry mounted.

Kamenshine, Lesley. A/V Troubleshooter. 1985. pp. 22-26.

No comments:

Post a Comment